Hareketsiz hale geldikten sonra kapılarını kapatan ve hesaplarında kazanç veya bakiye olmadan tüm müşterilerini mahsur ...

Read More »

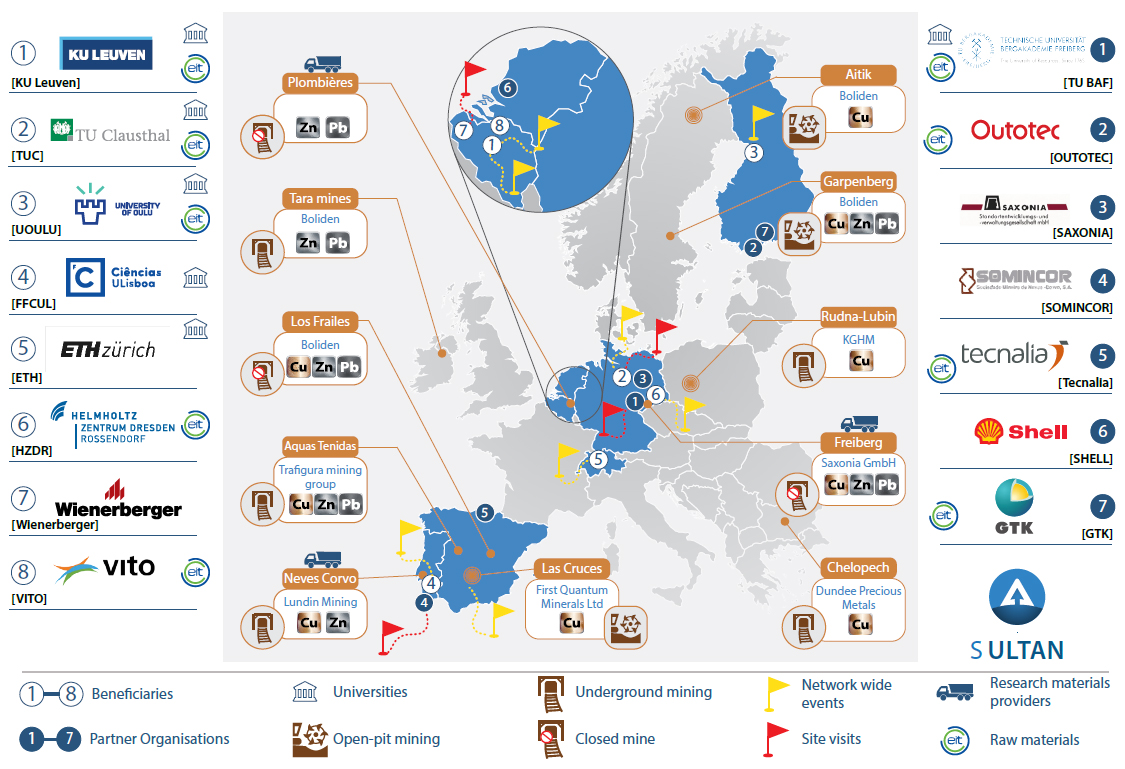

SULTAN - European Training Network for the Remediation and Reprocessing of Sulfidic Mining Waste Sites.

For more than 100 years the EU mining industries have been discarding their extractive-waste residues. Estimates suggest this represents 29% of the EU-28’s current waste output. When poorly managed these residues are a significant environmental hazard. Sulfidic Cu-Zn, Zn-Pb and Cu-Zn-Pb tailings pose the largest challenge, as they are prone to acid mine drainage. However, these tailings also contain valuable metals. Recently, the European Innovation Partnership (EIP) on Raw Materials launched a “call to arms” to transform the “extractive-waste problem” into a “resource-recovery opportunity”. Additionally, the EIP has warned about the acute shortage of talent in this sector. In order to develop a highly skilled workforce, to mitigate environmental risks and to economically recover valuable raw materials, the ETN for the remediation and reprocessing of sulfidic mining waste sites (SULTAN) provides the first-ever training programme dedicated to the reprocessing of tailings. SULTAN has pooled the interdisciplinary and intersectoral expertise of leading EIT RawMaterials members, world-leading mining and chemical companies, covering all the links in the tailings-reprocessing value chain.

SULTAN Infographic:For more than 100 years the EU mining industries have been discarding their extractive-waste residues. Estimates suggest this represents 29% of the EU-28’s current waste output. When poorly managed these residues are a significant environmental hazard. Sulfidic Cu-Zn, Zn-Pb and Cu-Zn-Pb tailings pose the largest challenge, as they are prone to acid mine drainage. However, these tailings also contain valuable metals. Recently, the European Innovation Partnership (EIP) on Raw Materials launched a “call to arms” to transform the “extractive-waste problem” into a “resource-recovery opportunity”. Additionally, the EIP has warned about the acute shortage of talent in this sector. In order to develop a highly skilled workforce, to mitigate environmental risks and to economically recover valuable raw materials, the ETN for the remediation and reprocessing of sulfidic mining waste sites (SULTAN) provides the first-ever training programme dedicated to the reprocessing of tailings. SULTAN has pooled the interdisciplinary and intersectoral expertise of leading EIT RawMaterials members, world-leading mining and chemical companies, covering all the links in the tailings-reprocessing value chain.

Read more...