Within the EU Horizon 2020 MSCA-ETN SULTAN project, a team of Wienerberger, VITO & SIM2 KU Leuven researchers succeeded in blending up to 20 wt% of mining waste into ceramics. This research study assessed the sustainable use of low sulphidic tailings (yellow tailings) from the former Plombières mine (Eastern Belgium) in clay roof tiles, clay blocks, and clay pavers. The work was published in the special issue in the Journal of Sustainable Metallurgy, entitled “Mine Tailings: Problem or Opportunity? Towards a Combined Remediation and Resource Recovery Approach”.

Blending tailings into ceramics

The results showed suitability of the untreated mine tailings for roof tiles (5%), inner-wall blocks (10%), and pavers (10 and 20%) considering their production processes, product quality, and environmental performance in a 2nd life scenario where demolished ceramics can be recycled as aggregates.

Even though higher additions of tailing material resulted in technical and aesthetical problems for roof tiles (10 and 20%) and blocks (20%), the tailing-containing pavers (10 and 20%) showed even better technical properties than the standard materials, while satisfying chemical and aesthetical properties. Therefore, clay pavers were considered the most suitable ceramic product to incorporate higher amounts of this tailing material.

Circular building materials

This is an important step towards circular building materials, where the waste of one industry can become the resources of another industry, thereby boosting a more circular and resource-efficient economy. Moreover, the selected Plombières fine tailings, with low sulphur and metal(loid) content, were directly suitable for incorporation in ceramics without the need of any pre-treatment, making the remining of these old tailings less energy intensive and more sustainable.

Full reference

This study was published in the special issue “Mine Tailings: Problem or Opportunity? Towards a Combined Remediation and Resource Recovery Approach“ from the Journal of Sustainable Metallurgy (Springer). Full reference: Francisco Veiga Simão, Hilde Chambart, Laure Vandemeulebroeke, Peter Nielsen, and Valérie Cappuyns. Turning Mine Waste into a Ceramic Resource: Plombières Tailing Case. J. Sustain. Metall. (2021). https://doi.org/10.1007/s40831-021-00442-3

Acknowledgements

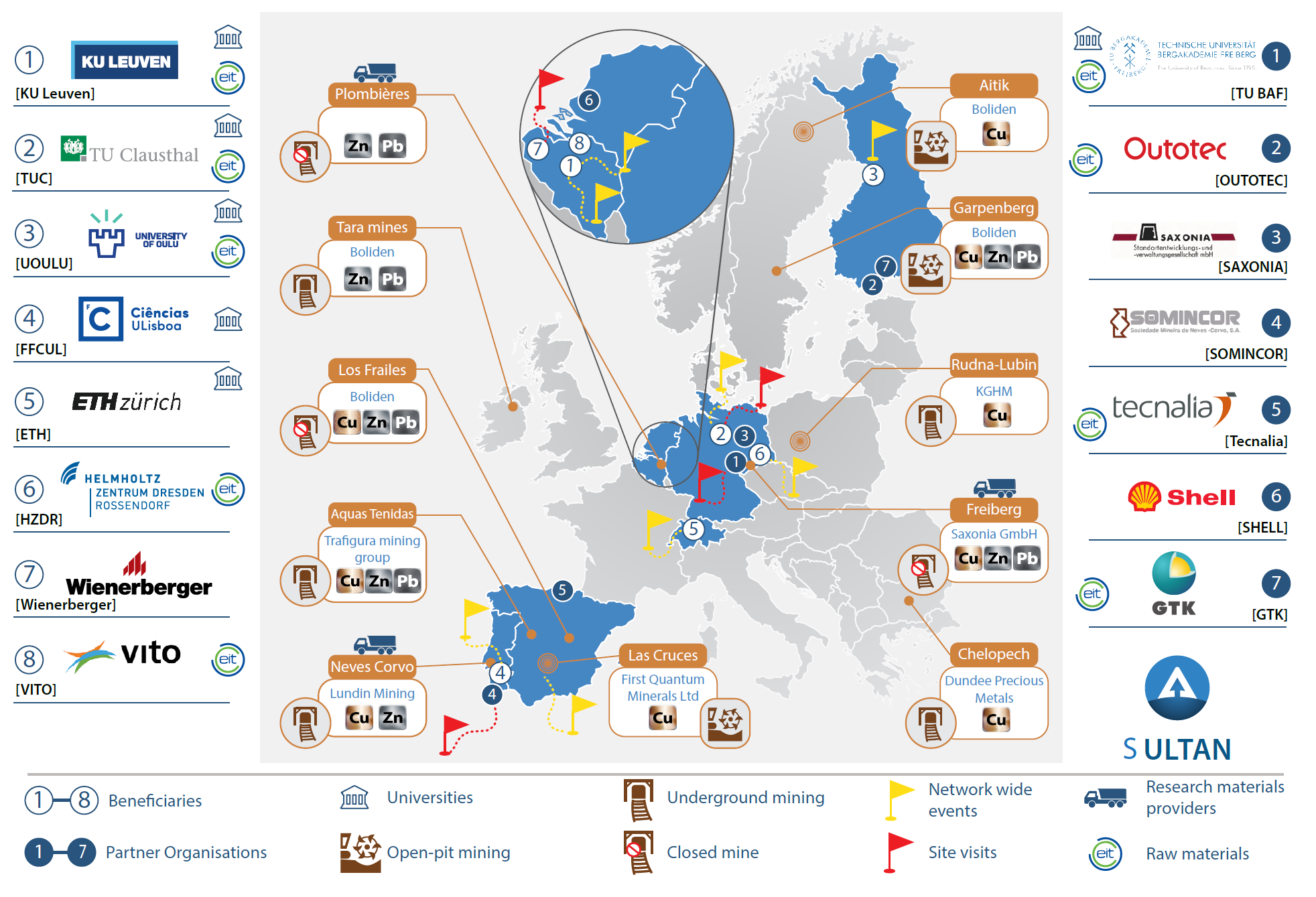

This study is part of the EU H2020 MSCA-ITN-ETN SULTAN project, aiming at the remediation and reprocessing of sulfidic mining waste sites. This project has received funding from the European Union’s Framework Programme for Research and Innovation, Horizon 2020, under Grant Agreement No. 812580.