A bioheapleaching pilot plant started operating at the Sotkamo mine in Finland. The pilot aims to mimic and improve the secondary bioheapleaching process at the mine, thereby increasing the recovery of Co, Ni, Cu and Zn, while enhancing the removal of sulphides. The pilot is one of the pilots operated within the EU Horizon 2020 NEMO project, aiming at the valorisation of sulphidic mining waste.

The Horizon 2020 NEMO project “Near-zero-waste recycling of low-grade sulphidic mining waste for critical-metal, mineral and construction raw-material production in a circular economy’’, develops, demonstrates and exploits different ways to valorise sulphidic mining waste. As part of the project,different pilot installations throughout Europe are being set up and brought into operation.

![]()

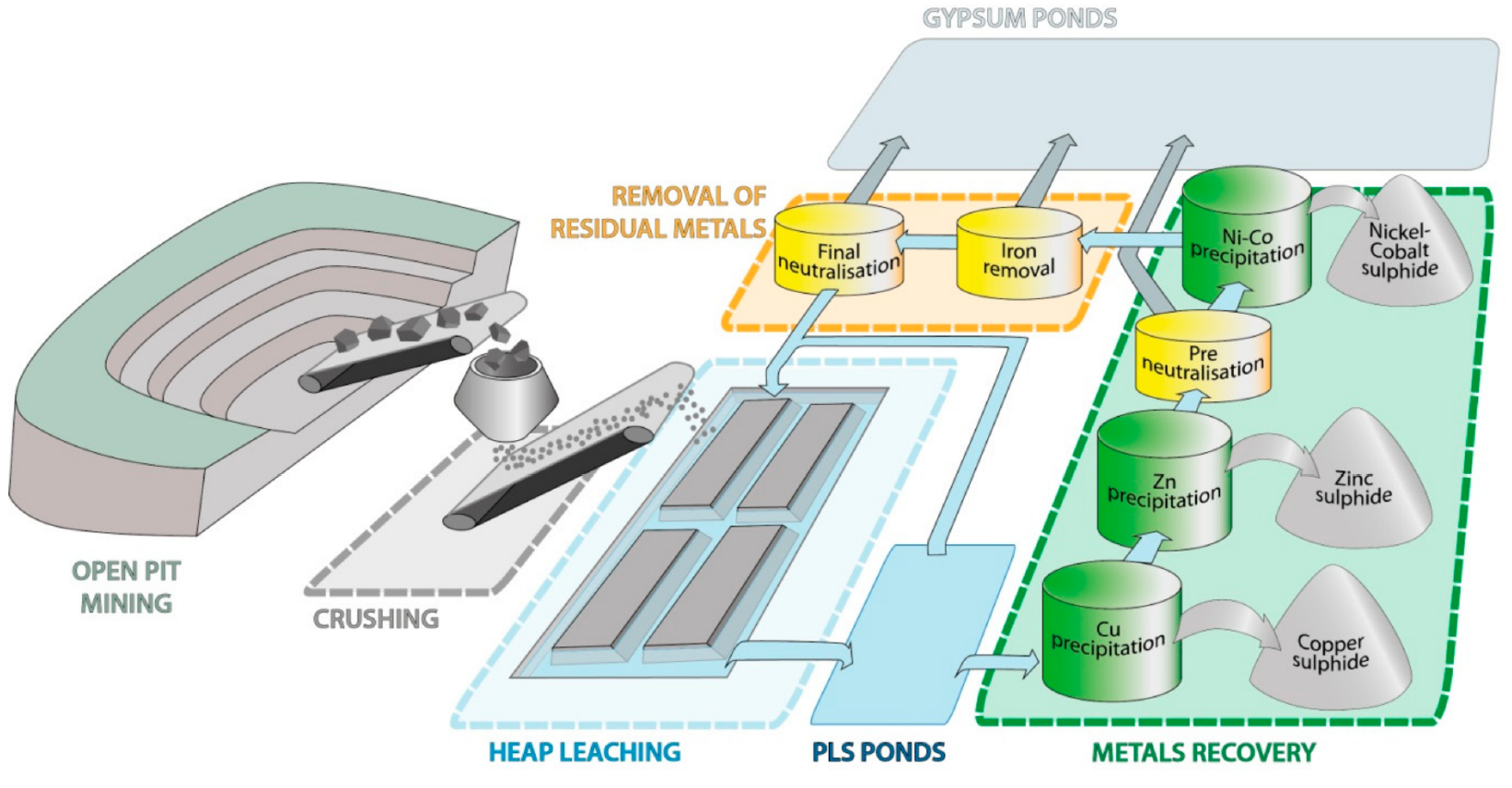

Figure 1: Primary bioheapleaching operations at the Sotkamo mine. Source: Terrafame.com

Sotkamo mine

One of the larger pilots in the project is located at the Sotkamo mine in Finland. Today, Sotkamo is an important producer of Zn, Cu and Ni-Co products. Sotkamo is operated by Terrafame, represented in NEMO by its owner company Finnish Minerals group.

Within NEMO, the Sotkamo mine acts as one of the case-studies. In the present day Sotkamo process, metals are reclaimed through a bioheapleaching process (Figure 1) in which a pregnant leach solution is produced. Sulphide precipitation is used to consecutively precipitate CuS, ZnS and (Ni-Co)S products (Figure 2).

The bioheapleaching is operated in two steps, distinguishing the primary heapleaching, after which the solid leaching residue is reclaimed and fed to the secondary heapleaching. Within NEMO, the focus is on the secondary heapleaching process.

Bioheapleaching pilot

To study and improve the secondary heapleaching process, a bioheapleaching pilot was set up and brought into operation (cf; featured image).

For the purpose of the pilot test, a pilot heap was constructed with similar operational parameters as the current secondary heapleaching operation at the mine (e.g. aeration, irrigation). The pilot is fed with the solid leaching residue from the primary heapleaching operations.

The aim of the pilot is to test a new microbe population and enhanced operational conditions developed by the NEMO partners BRGM, Exeter University and the Sotkamo team. With the optimisation of the secondary heapleaching, the NEMO partners aim to improve the leaching of metals (Cu, Co, Ni, Zn), while a mineral fraction is left behind with low residual sulphide content, which remains in place as a final waste product of the process.

Figure 2: Schematic representation of the metal recovery process at Sotkamo. Source: Geosciences 2018, 8, 66; doi:10.3390/geosciences8020066.

The pilot composes 900 tonnes of primary heapleaching residues. The pilot consists of two identically constructed heaps where the first heap is operated with new parameters and new microbial culture whereas the other acts as a reference heap operated with the same parameters as used in the current secondary leaching process.

The first test heap was inoculated with the microbe culture for three times to ensure adequate microbial population. The pilot heap was constructed during the summer of 2020, started operation in august 2020 and will run for 2 years.