Panagiotis Xanthopoulos, SIM²/SOLVOMET researcher active as Early Stage Researcher in the ETN SULTAN project, has been awarded the Best Oral Presentation Award at the 2020 International AMD online conference “Mine-impacted Water: From Waste to Resource”. The conference was organised by the Southern African Institute of Mining and Metallurgy (SAIMM). Xanthopoulos’ winning presentation was entitled: “Removal of trace concentrations of heavy metals from simulated dilute mine streams via ion and precipitate flotation”.

Acid Mine Drainage

Acid mine drainage (AMD) is the most widespread problem associated with sulphidic tailings. Sulphidic tailings arise during the mineral processing of sulphidic ores that involves crushing, milling and separation of the economic fractions (Cu, Zn and Pb sulphide ores) via froth flotation. The resulting sulphidic tailings are usually stored in the form of piles at tailing storage facilities, where they are physically dewatered.

AMD is generated due to the oxidation of pyrite minerals and other sulphide metals upon exposure of tailings to air, water and microbial activities. The main features of AMD are extreme acidity (0.5<pH<3) with an enhanced concentration of heavy and hazardous metals (e.g. Cd, As, Hg, etc).

Generally, it’s very difficult to prevent the exposure of tailings to air, water and bacteria and, therefore, to avoid the generation of AMD. As a result, remediation approaches have been developed that involve the neutralisation and the detoxification of this acidic effluent in order to prevent the negative environmental impacts of AMD.

Dealing with Acid Mine Drainage

The state-of-the art techniques for detoxifying aqueous effluents are: chemical precipitation, ion exchange, adsorption, reverse osmosis, membrane filtration, etc. Nevertheless, these techniques might not be sufficiently compliant with the strict threshold values of heavy metals for the safe disposal of the treated industrial waters set by environmental legislations. Hence, new techniques should be developed to treat dilute effluents as extra post-treatment steps.

Ion and precipitate flotation are classified among these techniques and involve the removal of a metal from a dilute aqueous solution to a foam phase by adding surfactants, while nitrogen gas or air is bubbled through from the bottom.

In ion flotation the targeted metal ions are adsorbed or adhered to the interface of the dispersed bubbles by interacting with the opposite charge collectors’ hydrophilic functional groups. In precipitate flotation metal ions first precipitate and then are assisted by the surfactants to be separated from the bulk solution to the foam phase.

During the conference, an efficient method was presented by Panagiotis Xanthopoulos (LinkedIn Profile Panagiotis Xanthopoulos) to remove trace concentrations of heavy metals (Cd, Mn and Zn), which typically occur in dilute mining effluents via ion and precipitate flotation.

Acknowledgements

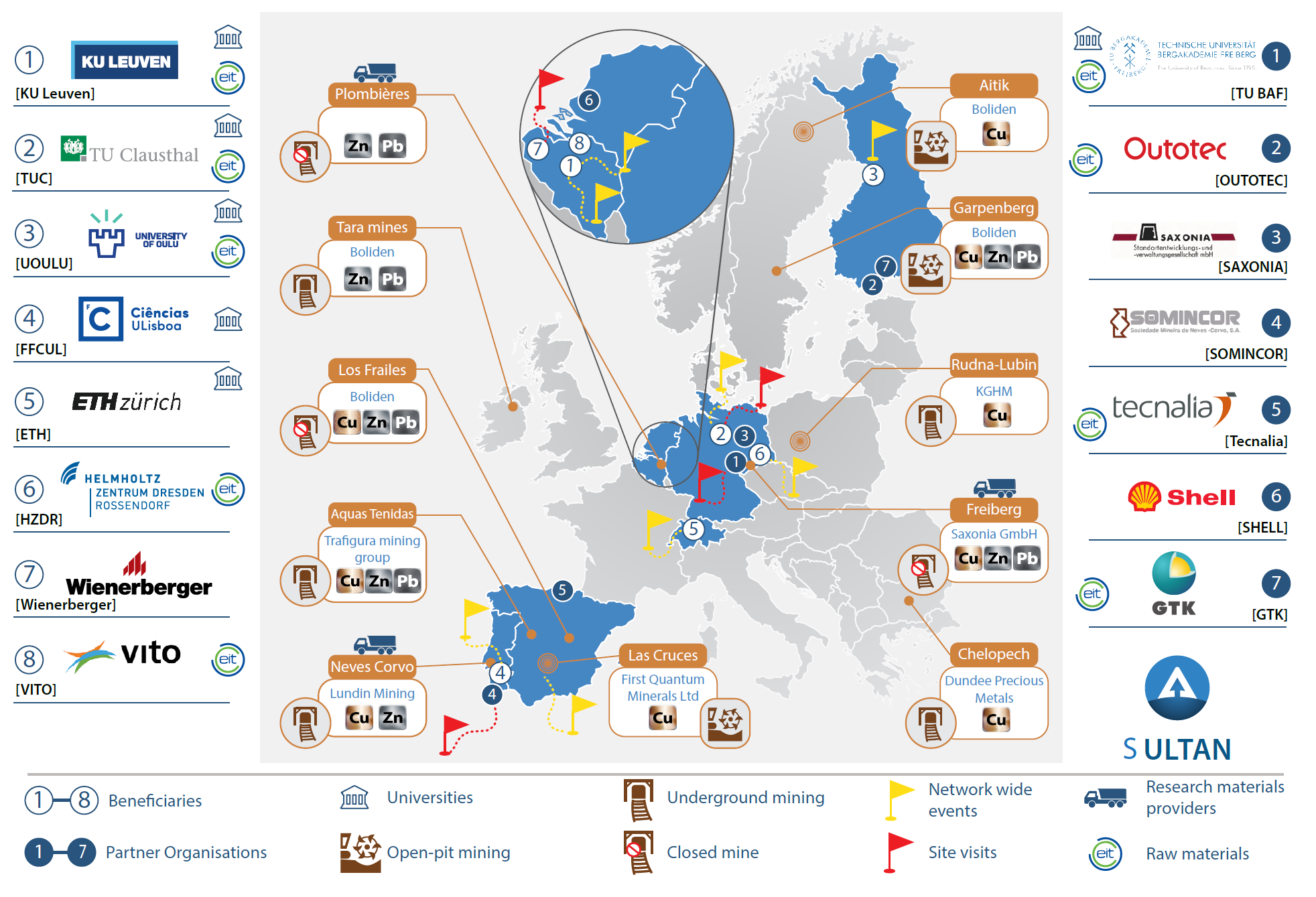

The research leading to these results has received funding from the European Community’s Horizon 2020 Programme under Grant Agreement no. 812580 (MSCA- ETN SULTAN).